Are You Running Your Shop Floor Blind?

For a light manufacturer, profit is made or lost on the shop floor. But without a connected system, you're operating with guesswork, manual data, and costly delays.

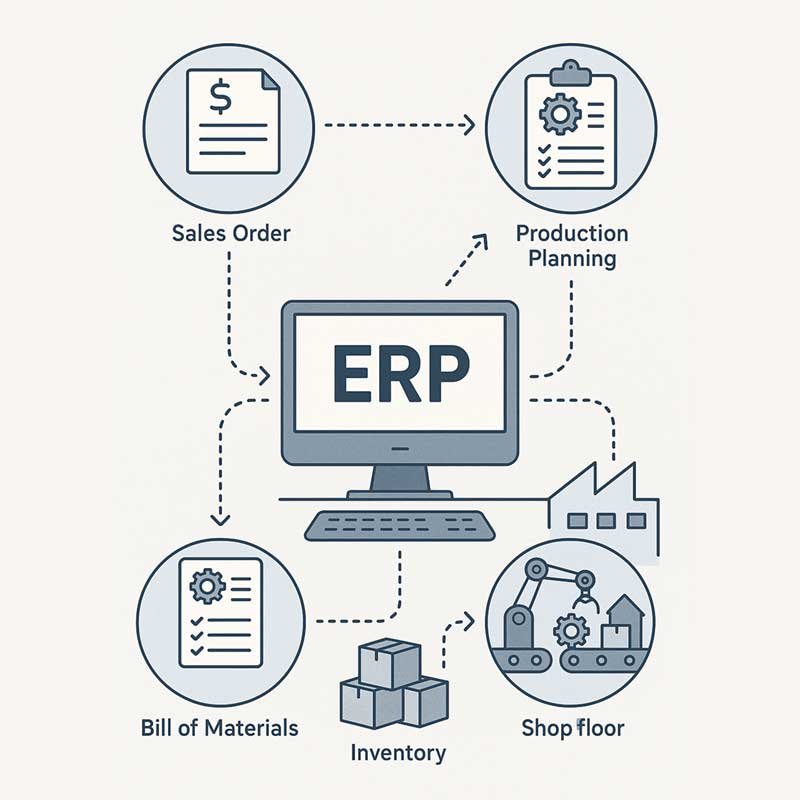

- Are you unable to calculate the true, final profit on a job after it's completed?

- Is your production line frequently stopped by unexpected stock-outs of one critical component?

- Are you still using manual job cards and spreadsheets to track production status?

- Is your Bill of Materials (BOM) a complex Excel file that's always out of date?

- Can your sales team not give a customer a clear status update on their order?