From Chaotic Godown to 99.9% Accurate Fulfillment Center

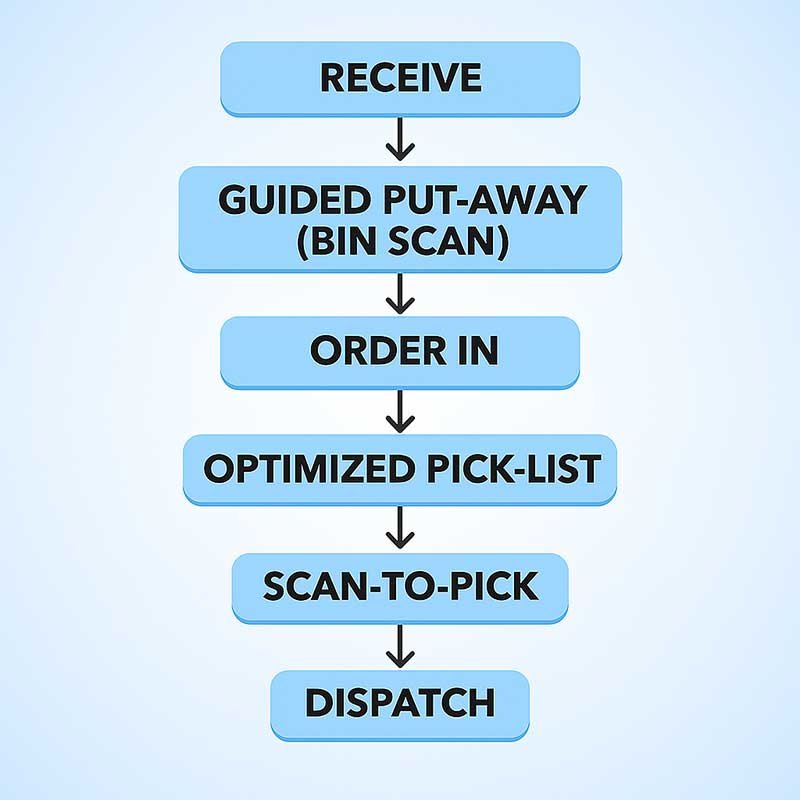

A warehouse is a high-speed physical operation where every mistake costs money. Our Warehouse Management Solution (WMS) digitizes every move—from receiving a new shipment to picking, packing, and dispatching an order—driving 99.9% accuracy, boosting labor efficiency, and cutting your fulfillment time in half.