From Raw Herb to Final Dose: Precision. Compliance. Traceability.

Preparing medicine—whether for a single patient in an Ayurvedic hospital or a 10,000-unit pharmaceutical batch—is a high-stakes process. There is no room for error.

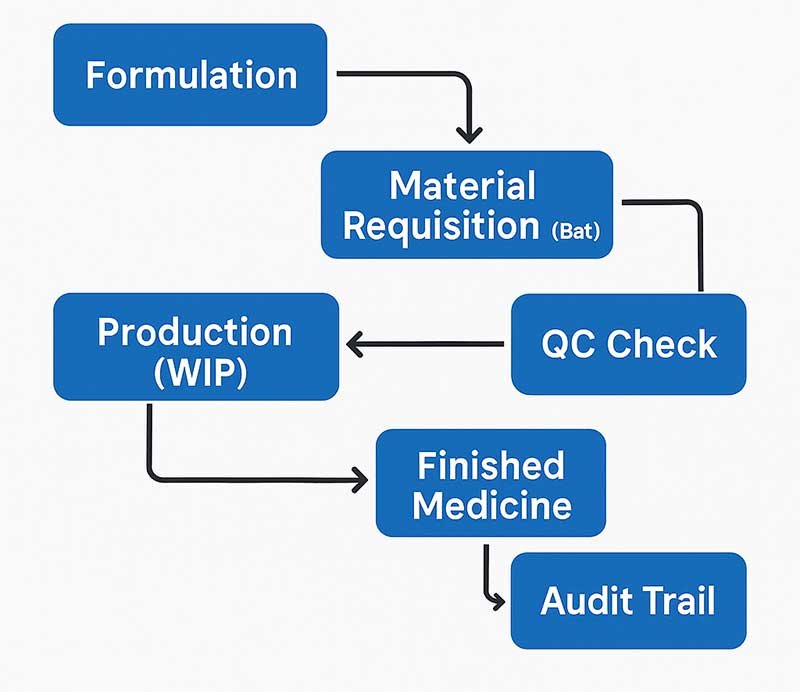

Our Medicine Preparation Solution is a high-precision system that digitizes your formulations, enforces quality control, and provides an ironclad, auditable trail for 100% compliance.